In Turkey, there are 13,000 artisanal fishing boats contributing to the income of at least 40,000 fishermen and their families constituting local communities. Often the fishing boats are of traditional design and thus inefficient in terms of fuel consumption. They may waste a substantial amount of their fuel due to the growth of marine organisms on the hull (e.g. slime, seaweed, barnacles, mussels) which is referred to as “biofouling” (Figure 1). Biofouling causes surface roughness, increasing the frictional resistance of the ship, and thus the increases in power and fuel consumption. The mitigation also requires costly hull cleaning and antifouling procedures. Inadequate design and antifouling strategies aggravate the profitability and cause environmental problems such as increased Green-House Gas emissions and transportation of harmful non-indigenous species, while negatively affecting the expected growth in the fisheries sector as opposed to Turkey’s Vision 2023 targets for fisheries.

Figure 1: Biofouling accumulation on a ship’s hull surface

We are now carrying out the second phase of our 3-phase plan to deliver energy-efficient and sustainable fishing boats in Turkey and eventually around the world for contributing to the economic development and welfare of the fishing communities.

Phase 1 – Pilot work

The first phase of the project was funded by the Global Challenges Research Fund (GCRF) – Scottish Funding Council (SFC) Institutional Pump Priming Fund. In Phase 1, we conducted a pilot work. We investigated the current antifouling practices used in the Black Sea region and identified the local needs for developing smart antifouling strategies towards energy-efficient fishing boats. This was achieved by carrying out an inter-disciplinary pilot work with a focus on the technical feasibility, economic viability and environmental perspectives.

In order to determine the details of the fishing boats and current practices and antifouling strategies used in the Black Sea region, we conducted a comprehensive literature review. By analysing the statistics regarding the fishing boats in Black Sea regions, we determined the principal particulars of a virtual target vessel to represent the typical artisanal fishing vessels in the Black sea region, and the typical type of antifouling coating used for the fishing vessels in the region.

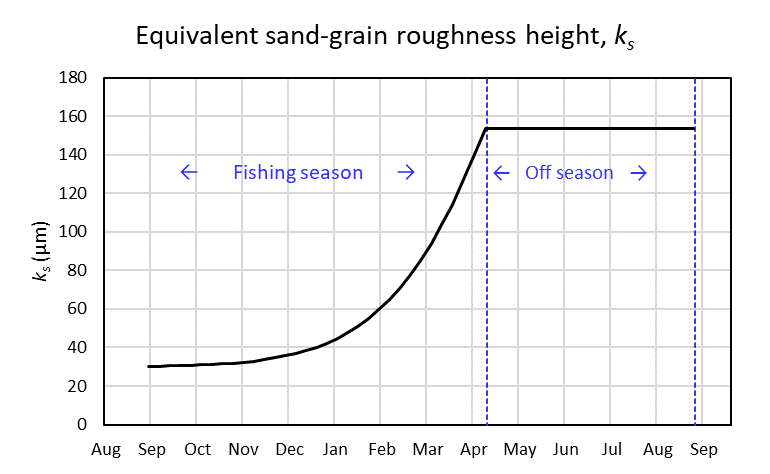

Based on the determined principal particulars of the fishing vessel and the typical antifouling coating, we conducted initial engineering calculations to predict the fuel penalties due to the accumulation of biofouling in time. For the analysis, the time-dependent growth model of Uzun et al. (2019) was used to predict the fouling rating on the fishing boat with the typical antifouling coating over a one-year operation period (01/Sep– 31/Aug). The predicted time-dependent fouling rating values were converted to the equivalent sand-grain roughness height, ks, as shown in Figure 2. It was assumed that the fishing boat is on the shore during the off-season and thus the fouling growth stops as asserted by Uzun et al. (2019). The ks values were used with the turbulent boundary layer similarity analysis to predict the added frictional resistance due to the hull fouling.

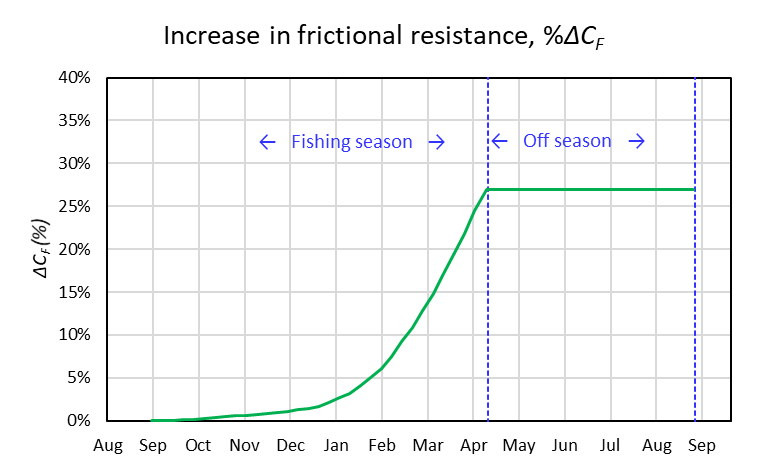

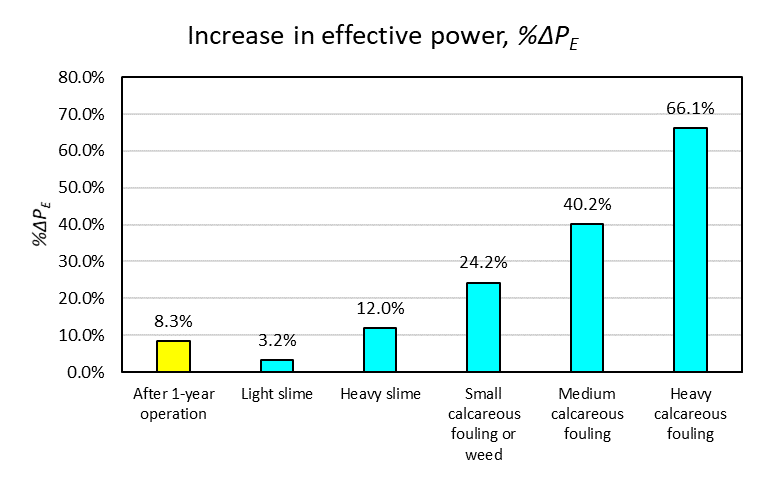

Figure 3 shows the predicted percentage increase in the frictional resistance, %ΔCF, of the fishing boat in time. The result suggests that the frictional resistance increases by 27% at the end of the fishing season. The increase in the effective power, ΔPE, was also estimated based on the frictional resistance increase. Figure 4 compares the percentage increase in the effective power, %ΔPE, of the fishing boat after the one-year operation and the %ΔPE values with the representative fouling conditions based on the data of NSTM (2002) and Schultz (2007). The result shows that the power penalty (8.3%) due to the hull fouling is in between those of the Light slime (3.2%) and the Heavy slime (12.0%) fouling conditions.

Figure 2: Equivalent sand-grain roughness height,ks , on the fishing boat with the typical antifouling coating over the 1-year operation period

Figure 3: Predictions of the percentage increase in the frictional resistance (%ΔCF) of the fishing boat over the 1-year operation period

Figure 4: %ΔPE of the fishing boat after the 1-year operation and ΔPE predictions based on the representative fouling conditions

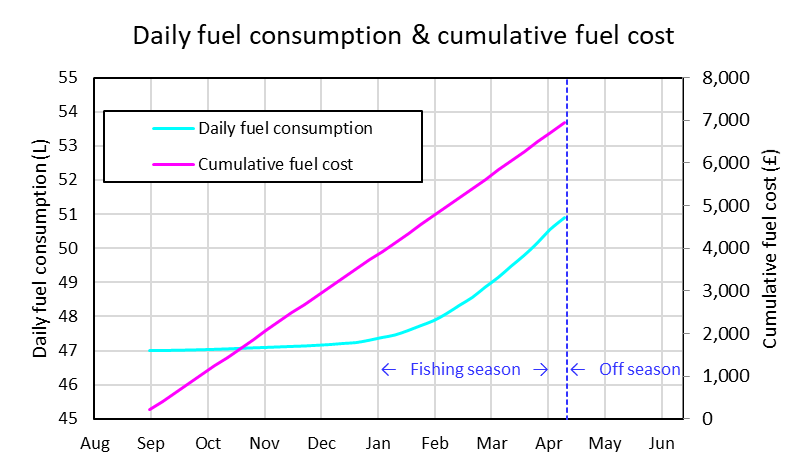

A financial analysis was also conducted based on the initial engineering calculation results. Using the power penalty prediction, the daily fuel consumption of the fishing boat was estimated as well as the corresponding fuel cost. Figure 5 shows the daily fuel consumption of the fishing boat and the cumulative fuel cost during the 1-year operation period. The result shows that the daily fuel consumption increases from 47 L/day to 51 L/day during the fishing season, while the total fuel cost reaches to £69,000.

Figure 5: Daily fuel consumptions of the fishing boat and accumulative additional cost over the operation period

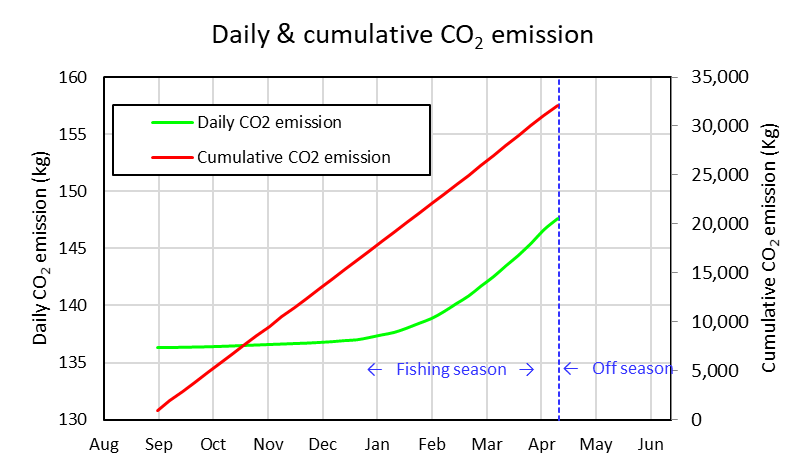

The environmental impact was also estimated based on the fuel consumption predictions. Figure 6 shows the daily CO2 emission of the fishing boat and the cumulative additional CO2 emission over the 1-year operation period. The result suggests that the daily CO2 emission of the fishing boat increases from 136 kg/day to 148 kg/day and the total cumulative CO2 emission reaches to 3.2 tons during the fishing season.

Figure 6: Daily and cumulative CO2 emissions of the fishing boat with different antifouling coatings

In December 2020, a public workshop was held to disseminate the project results to the stakeholders. The Black Sea fishing community, NGOs, universities from Turkey and Europe, governmental bodies, and local media were invited to this event. In addition to this, the Chamber of Turkish Naval Architects and Marine Engineers promoted the event and invited all its members to the public workshop.

Phase 2 – Roll-out across Turkey

The second phase is now underway funded by GCRF SFC Escalator Fund, with an aim to roll out the outcomes of Phase 1 across Turkey and develop Smart Antifouling Strategies. This work is essential at this point to establish a firm evidence base for large scale applications since it will demonstrate the potential positive impact of the developed strategies on the economic development and welfare of the Turkish fishing community. The specific objectives of Phase 2 are:

- To rollout the research procedure developed for the Black Sea Region across the fishing community in Turkey

- To propose alternative antifouling strategies and to conduct Life Cycle Assessment and Life Cycle Cost Analysis to determine the most feasible antifouling strategies

- To develop a ‘Smart Antifouling Strategies Framework’ and online training to increase awareness, provide a policy roadmap for the Turkish Government and contribute to research capacity building in Turkey

- To hold outreach and stakeholder engagement events to maximise the impact of the previous and the proposed project outcomes

Phase 3 – Roll-out across the world

In Phase 3, the target will be extended to fishing sectors around the world, we will develop a new design for the small fishing boat that will be more durable, energy-efficient and will use novel materials. These three phases have the potential to increase the profitability of fishing boats and thus the household income of fishermen and their families living in vulnerable communities.

The consortium will seek funding for the next phase from future GCRF calls, Newton Fund calls, Horizon Europe, the Interamerican Development Bank, venture funds and foundations, if applicable.

Reference(s)

- Uzun, D., Demirel, Y. K., Coraddu, A., & Turan, O. (2019). Time-dependent biofouling growth model for predicting the effects of biofouling on ship resistance and powering. Ocean Engineering, 191, 106432. doi:https://doi.org/10.1016/j.oceaneng.2019.106432

- Schultz, M. P. (2007). Effects of coating roughness and biofouling on ship resistance and powering. Biofouling, 23(5), 331-341. doi:10.1080/08927010701461974

- (2002). NAVAL SHIPS’ TECHNICAL MANUAL CHAPTER 081: WATERBORNE UNDERWATER HULL CLEANING OF NAVY SHIPS.

Dr. Yiğit Kemal Demirel, Senior Lecturer yigit.demirel@strath.ac.uk www.strath.ac.uk/naome/

Dr. Soonseok Song, Research Associate soonseok.song@strath.ac.uk www.strath.ac.uk/naome/